NRE Support Rig

Efficiency through fully automated cycle

Efficiency through fully automated cycle

The purpose of NRE Support Rig is to install self drilling roof bolts (SDR’s) to hanging wall of narrrow reef stopes. It is possible for operator to perform all functions from a safe operating distance. Its robust design, small dimensions, low noise level, and nil gaseous emission make this machine the most suitable tool for underground applications. The NRE Support Rig is battery power driven and operated by remote control.

The NRE Support Rig is designed to work in stoping widths from 0.9, to 1.7m, and can work in reef inclinations of up to 22°. The NRE Support Rig has a dual tool configuration, allowing 2 bolts to be drilled, installed and resin injected simultaneously. Its lightweight, stand-alone remote control allows the operator to remain at a safe operating distance during the production process.

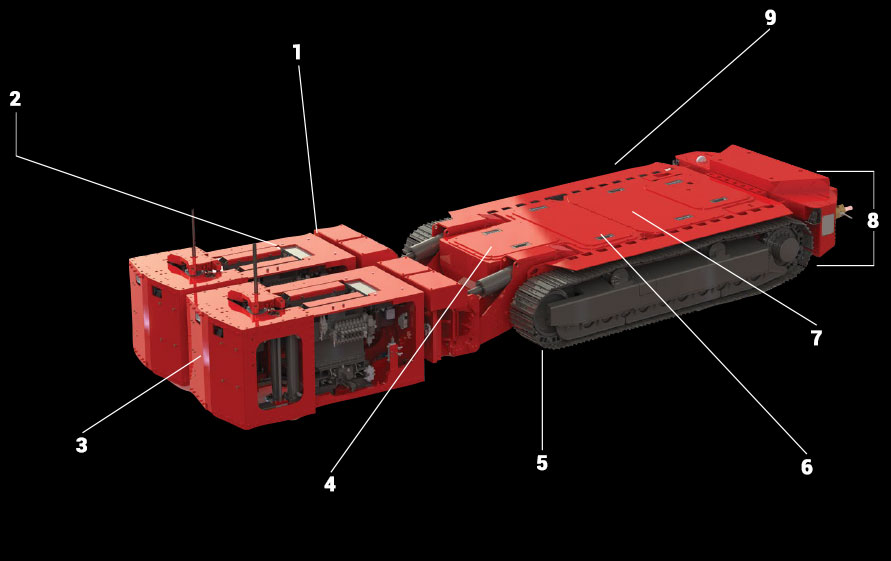

1. VIDEO SYSTEM 2. SUPPORT RIG TOOL

3. RESIN PUMPING SYSTEM 4. STANDARDISATION

5. HIGH MOBILITY

6. EASY MAINTENANCE ACCESS

7. ELECTRIC DRIVE

8. HEIGHT 660 mm

9. REMOTE CONTROL CAPABILITY

Single button automated supporting cycle

2 x tools (drills simultaneously)

Installation bolt length - 1.6m to 2.4m

SDR segment length: 400mm, up to 6 SDR segments per single bolt installation cycle

Bolt installation time: 2 bolts (1.6m) installed in 8 minutes simultaneously

Camera system per tool

Adjustable tool kinematics

Support pattern flexibility (1m -2 m)

Rotary drilling (controlled advance rate)

Narrow reef prime mover platform

Interchangeable support rig and drill rig tool attachments

| Dimensions | |

|---|---|

| Prime Mover | 4150 x 1976 x 745 mm |

| Toolset | 2185 x 1950 x 793 mm |

| Tool Width (single) | 935 mm |

| Ground clearance | |

|---|---|

| Clearance | 130 mm |

| Weight | |

|---|---|

| Prime Mover | 10 000 kg |

| Toolset | 3000 kg |

| Power system | |

|---|---|

| Battery Type | LiFePO4 |

| Battery Pack Nominal Voltage | 346 V DC |

| Working off the electrical grid via trailing cable | 380 – 550 VAC 3ph |

| On board fast charger | |

|---|---|

| Charging time | 1 hour |

| Charging source | 380 – 550 VAC 3ph |

| Support tool characteristics | |

|---|---|

| Number of tools | 2 |

| Type of drilling | Rotary drilling |

| Maximum drill thrust force | 40 kN |

| Support cycle (2 bolts, 1.6 m ea.) | 8 min |

All technical characteristics are provided for informational purposes only and DOK-ING Ltd. reserves the right to make changes without notice.

Industry: Underground mining

Customer: One of the world’s largest mining companies (South African market)

Challenges: Impossibility to fully mechanize the mining cycle (drill, blast, clean & support) in the narrow reef mining equipment which is a very labour intensive, unsafe and inefficient

Customer’s requirements: Development of a fully electrically powered and remotely controlled equipment which will ensure the full mechanization of the mining cycle

Results: Developed electrically powered and remotely controlled NRE Equipment Suite which provides health and environmental benefits of clean power technologies

In 2008, DOK-ING was approached by Anglo American to develop electrically powered equipment which could operate in working heights as low as 900 mm in narrow reef mining environments. Anglo American is one of the largest diversified mining houses in the world.

At the time when DOK-ING was appointed to develop this equipment, it was not possible to fully mechanize the mining cycle (drill, blast, clean & support) in the narrow reef mining environment. Traditionally, mining in narrow reef ore bodies is a very labour intensive, unsafe and inefficient process. In order to improve narrow reef mining safety and efficiency, remotely controlled, mechanized mining equipment was selected by Anglo American to make this possible.

The client required suitably sized <650 mm in height equipment, which was fully electrically (battery) powered and could be operated at a safe distance from the working face. The development commenced with the prototype for battery powered Dozer utilized in the cleaning cycle. Afterwards, prototypes for the drill rig were completed and tested. Finally, a support rig (roof bolter) was developed and tested, ensuring the full mechanization of the mining cycle could be achieved by means of remotely controlled equipment. This suite of equipment can operate in the stoping width of between 0.9 m and 1.7 m at working angles of up to 22°.

By 2019, a 3rd generation of the full suite of NRE equipment had been produced and is now ready to roll out in narrow reef mining operations within Anglo American and other mining houses. The NRE Suite comprises of the following equipment:

Currently, there is no other company in the world which has developed and tested a complete suite of electrically powered, remotely controlled equipment. The main benefits of this equipment are as follows: