Strong. Robust. Unstoppable.

Strong. Robust. Unstoppable.

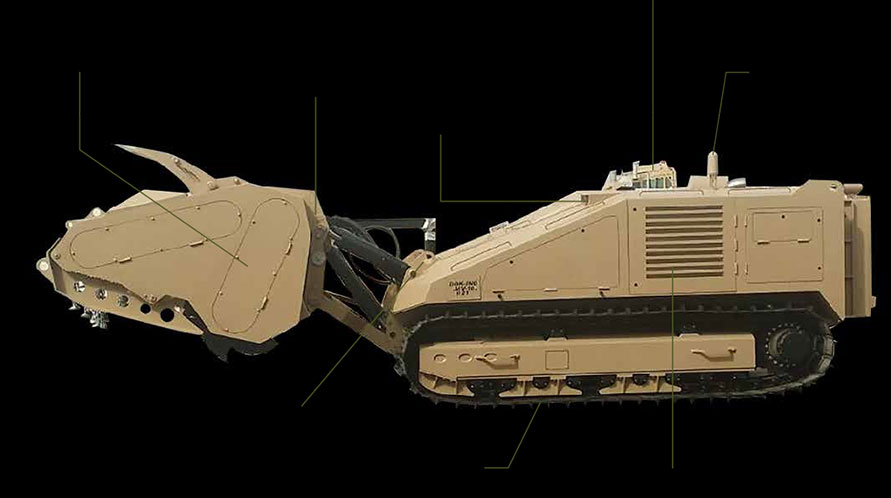

The MV-10 is the only robotic system in the world with double tool: front-positioned flail tool followed by a rear tiller. It is the only demining system in its class that has been verified in the real combat situation. Furthermore, due to its high engine power and supreme explosion resistance, the MV-10 presents the strongest system in its category.

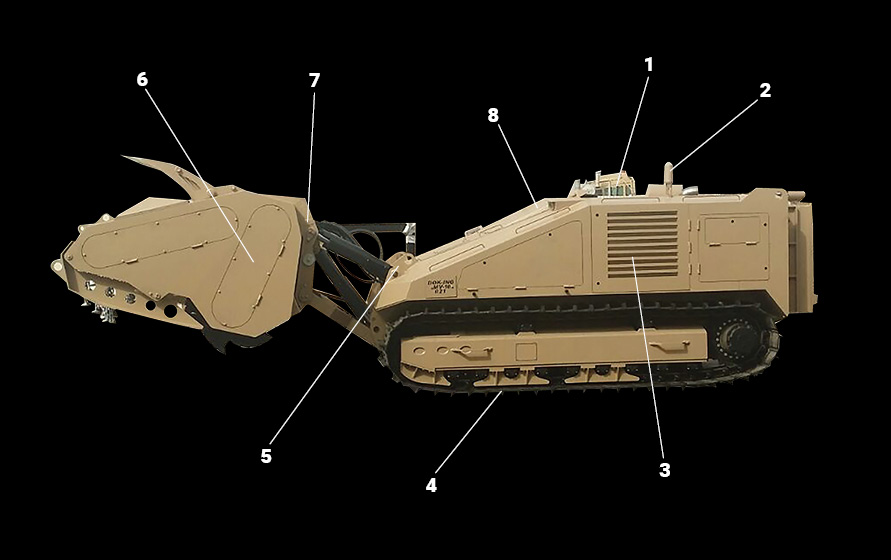

KEY FEATURES

KEY FEATURESMission-oriented engineering platform

Prime mover and various exchangeable tools

1. SITUATIONAL AWARENESS

2. OFF/ON ROAD MOBILITY

3. EXTENDED EOD CAPABILITIES

4. FULL BODY PROTECTION

5. AIR AND ROAD TRANSPORTABLE

6. MULTI-MISSION CAPABILITY

7. REMOTE CONTROL CAPABILITY

8. DAY/NIGHT OPERATION

APPLICATIONS

APPLICATIONS

Flail/Tiller Double Tool

Purpose: Area/mine clearance, neutralization of AP&AT mines, vegetation clearance

Clearance width: 2450 mm

Clearance depth: Up to 400 mm

Flail/Tiller Double Tool

Purpose: Area/mine clearance, neutralization of AP&AT mines, vegetation clearance

Clearance width: 2450 mm

Clearance depth: Up to 400 mm

Flail/Tiller Double Tool

Purpose: Area/mine clearance, neutralization of AP&AT mines, vegetation clearance

Clearance width: 2450 mm

Clearance depth: Up to 400 mm

Rotational Gripper / Dozer Blade

Purpose: Breaching, removal of obstacles, earth moving, pushing

Lifting capacity: 2,5 t

Pushing capacity: 12 t

Rotational Gripper / Dozer Blade

Purpose: Breaching, removal of obstacles, earth moving, pushing

Lifting capacity: 2,5 t

Pushing capacity: 12 t

Segmented Roller

Purpose: Path/area clarification

Numbers of rollers: 15

Clearing width: 2070 mm

Rotational Gripper / Dozer Blade

Purpose: Breaching, removal of obstacles, earth moving, pushing

Lifting capacity: 2,5 t

Pushing capacity: 12 t

Segmented Roller

Purpose: Path/area clarification

Numbers of rollers: 15

Clearing width: 2070 mm

LOGISTICS

LOGISTICSThe MV-10 dimensions are within the required limits for various types of transportation.

Air – Delivery by various types of cargo planes (e.g. C-130, C-5, IL-76)

Water – The MV-10 prime mover could fit into standard 20’ container, while double tool could fit into the second one. Another option is to ship prime mover and tool in one 40’ container.

Land – Ideal for delivery by standard flat-bed or low loader trailer

TECHNICAL DATA

TECHNICAL DATA| Dimensional data* | |

|---|---|

| Length | 8075 mm |

| Width | 2970 mm |

| Height | 2330 mm |

| Weight | ~20920 kg |

| Engine type | Caterpillar C18 |

| Engine power | 571 kW / 766 HP |

| Engine torque | 3495 Nm @ 1400 rpm |

| Fuel consumption | 25 - 50 l/h |

| Demining capacity | Up to 4000 m²/h |

| Ground pressure | 0,65 kg/cm² |

| Transport speed | 7 km/h |

| Operational speed | 0,5 - 3 km/h |

| Longitudinal gradeability** | 37° |

| Side slope capability** | 25° |

| Fording depth | 80 cm |

All technical characteristics are provided for informational purposes only and DOK-ING Ltd. reserves the right to make changes without notice.

* Standard configuration with flail/tiller double tool

** Depending on the ground