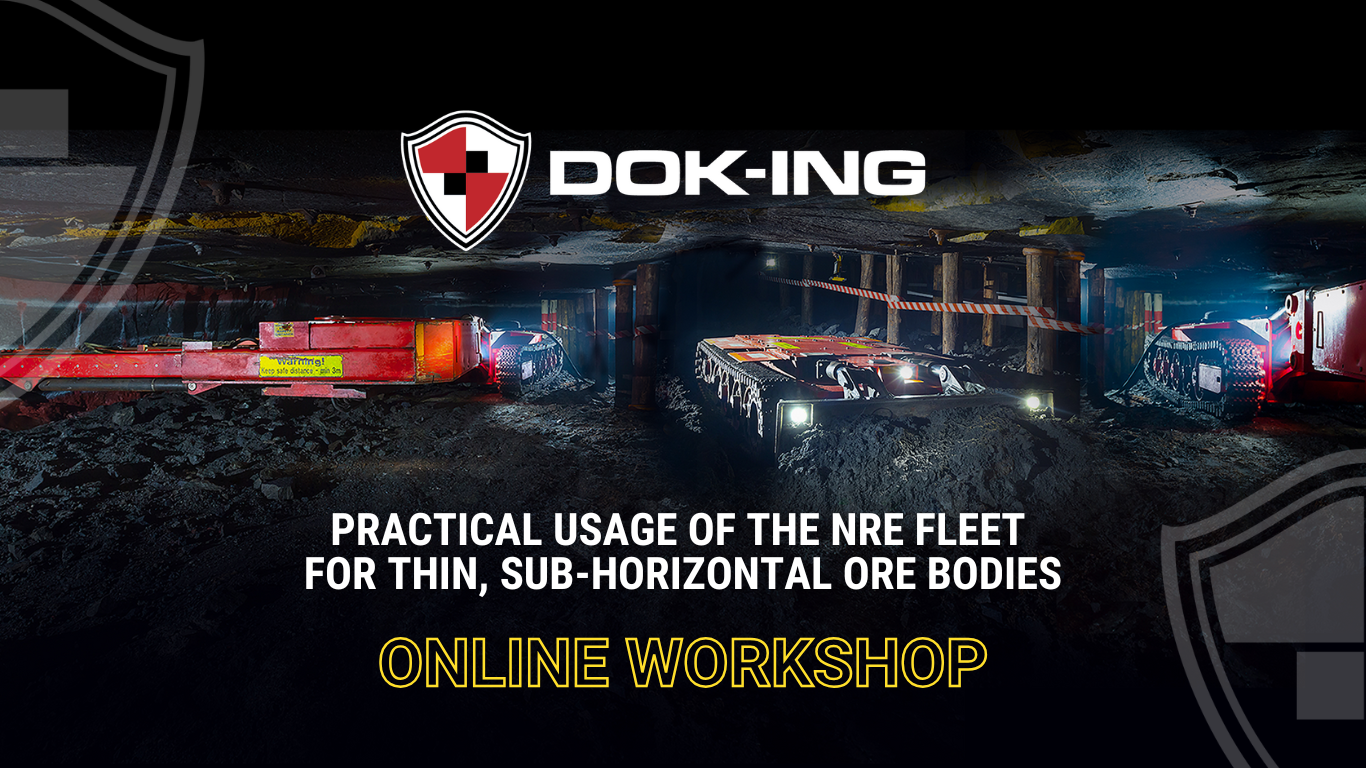

07 Nov 2024 DOK-ING Online Workshop & Panel Discussion on Practical Usage of the NRE Fleet for Thin, Sub-Horizontal Ore Bodies

DOK-ING and NRE-Electra Team will host an online workshop titled “Practical Usage of the NRE Fleet for Thin, Sub-Horizontal Ore Bodies” on November 12, 2024

DOK-ING and NRE-Electra Team will host an online workshop titled “Practical Usage of the NRE Fleet for Thin, Sub-Horizontal Ore Bodies.” This insightful workshop, featuring panel discussions with DOK-ING experts, industry professionals, and academics, will take place on November 12, 2024, at 9:00 a.m.

The discussions will cover the latest developments, applications, and future outlook for narrow reef mining.

The NRE (Narrow Reef Mining) fleet is a cutting-edge suite of mining machinery designed for efficient operation in thin, sub-horizontal ore bodies. Developed for versatility and precision, the NRE fleet includes electric, remote-controlled vehicles that can navigate challenging underground environments with minimal human intervention. Its key features include improved safety, enhanced productivity, and reduced operational costs, making it an ideal solution for mining deposits that are otherwise difficult to access or extract using traditional methods.

Please register your participation by 10.11.2024. at Online Workshop on “Practical usage of the NRE fleet for thin, sub-horizontal ore bodies” | EIT RawMaterials RIS Hub Adria

Date: November 12, 2024

Time: 9:00 AM – 1:30 PM (CET)

Location: Online

This workshop is organised in a framework of the EIT RawMaterials project NRE-ElectRA Electric, Remote control, Automatic Narrow Reef mining Equipment which aims to will develop and commercialize innovative, remote-controlled, electric-powered equipment that has the main function of mechanized production of strategic metals from Ultra-Low mining profiles ranging from 0.9 to 1.7 meters.

DON’T SEND A MAN TO DO A MACHINE’S JOB!

DOK-ING is an engineering powerhouse of heavy-duty robotics & autonomous systems. The company is an international market leader and has more than 80% of the market share in more than 40 countries globally. The headquarter is in the Croatian capital Zagreb, and, besides the European office, DOK-ING is incorporated on the following continents: North America, Africa & Asia. In more than 30 years of being in the business, the company has been recognized for changing the industrial landscape with its innovative approach and won many international “doing business and industrial” awards in innovations and technologies.

In a few words, by integrating its own innovations and new technologies, develops and manufactures robotic and autonomous systems to protect human lives & property in dull, dirty and dangerous environments, known to responders, primarily in Military Engineering, CBRNe, Counter Terrorism, Emergency Response & Underground Mining.

ABOUT DOK-ING UNDERGORUND MINING PROGRAM

DOK-ING’s Underground Mining’s innovative portfolio comprises two groundbreaking solutions: the XLPD Compact Robotic Dozer and the Narrow Reef Equipment (NRE) Fleet. The XLPD Compact Robotic Dozer is a low-profile, remote-controlled machine aimed at increasing efficiency and safety in material handling tasks. The NRE Fleet consists of three machines: Dozer, Drill Rig and Support Rig. The NRE Dozer features an ultra-low profile and remote control capabilities, the NRE Drill Rig is engineered for precise panel drilling in preparation for blasting, while the NRE Support Rig is designed to install self-drilling roof bolts (SDRs) in narrow reef stopes. This fleet enables safe exploitation of narrow reef layers by allowing each machine to perform its specific task in sequence, operated remotely to ensure worker safety. The NRE fleet is unique in its ability to perform mechanized rock excavation in rooms less than 1.7 meters high. Additionally, the NRE fleet is fully electric, eliminating gas emissions and noise pollution from internal combustion engines, and have tracks undercarrige, allowing operation on inclines up to 25°. By using the NRE fleet, the working environment and miner safety are significantly improved, as miners no longer need to enter dangerous areas.