27 Nov 2024 DOK-ING Unveils its Workplace Safety Practices With Students From University of Applied Sciences in Security & Safety

DOK-ING WELCOMED GRADUATE STUDENTS FROM THE UNIVERSITY OF APPLIED SCIENCES IN SECURITY AND SAFETY, MAJORING IN WORK SAFETY, AND PROVIDED AN INSIGHT INTO THE COMPANY’S WELL-STRUCTURED APPROACH TO WORKPLACE SAFETY.

Zagreb, Croatia, 09.11.2024. – Graduate students from the University of Applied Sciences in Security and Safety, majoring in work safety, recently visited DOK-ING as part of their studies on identifying and mitigating dangers in production facilities and workplaces.

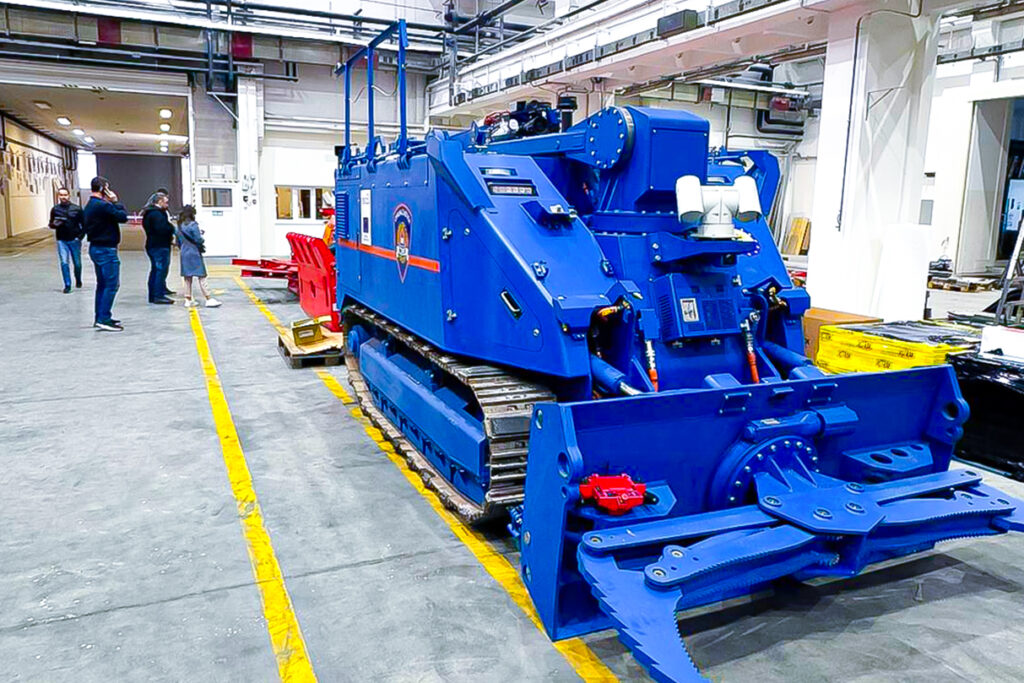

At DOK-ING, the students, led by Professor Tomislav Katić, had a unique opportunity to deepen their knowledge through a company presentation on its current occupational safety system. They learned how this global leader in demining machine production identifies hazards, conducts research to address them, and implements measures to mitigate risks.

Following the presentation, the students toured the production facility under the guidance of DOK-ING’s occupational safety and health expert, Matija Spudić. During the tour, they observed the company’s impressive portfolio of life-saving robotic systems and its well-structured approach to workplace safety.

Following the presentation, the students toured the production facility under the guidance of DOK-ING’s occupational safety and health expert, Matija Spudić. During the tour, they observed the company’s impressive portfolio of life-saving robotic systems and its well-structured approach to workplace safety.

“The nature of the business at DOK-ING, manufacturing of heavy equipment and machinery, demands a high level of occupational health and safety protection, making it one of the company’s top priorities and fundamental to its success. To ensure compliance with global work safety standards and best practices, and in alignment with the Health, Safety, and Environmental Management System, DOK-ING provides comprehensive training for its personnel and equips them with the necessary safety gear to perform their tasks safely. Welders are provided with protective clothing, boots, gloves, face shields, and specialized welding tools, electricians with insulated tools, gloves, and testing devices, machine operators with protective eyewear, hearing protection, field clothing for varying environments, and machinery control tools, painters with respirators, protective suits, and spraying equipment, assemblers and general workers with safety boots, gloves, helmets, and hand tools and so on. The shared goal of safeguarding and enhancing the health of DOK-ING employees is rooted in fundamental human and life values. DOK-ING also offers extensive healthcare benefits, embodying the adage, “prevention is better than cure,” ensuring the long-term health, safety, and well-being of all employees.” – stated Mr Spudić.

The University of Applied Sciences in Security and Safety, renowned for its decades-long tradition in the education of security experts, recognized DOK-ING as a company that raises the level of health protection and safety of all employees year after year.

Since 2021, the university has been part of the prestigious Swiss School of Business and Management Geneva (SSBM Geneva), which has been awarded one of the most esteemed international business school accreditations (ACBSP) in Washington, with students from over 130 countries worldwide.

DON’T SEND A MAN TO DO A MACHINE’S JOB!

DOK-ING is an engineering powerhouse of heavy-duty robotics & autonomous systems. The company is an international market leader and has more than 80% of the market share in more than 40 countries globally. The headquarter is in the Croatian capital Zagreb, and, besides the European office, DOK-ING is incorporated on the following continents: North America, Africa & Asia. In more than 30 years of being in the business, the company has been recognized for changing the industrial landscape with its innovative approach and won many international “doing business and industrial” awards in innovations and technologies.

In a few words, by integrating its own innovations and new technologies, develops and manufactures robotic and autonomous systems to protect human lives & property in dull, dirty and dangerous environments, known to responders, primarily in Military Engineering, CBRNe, Counter Terrorism, Emergency Response & Underground Mining.